Sailent Features of Ranchi Rafractories basic Bricks

Introduction

In the world of high-temperature industrial processes — from steelmaking and cement production to non-ferrous metallurgy — the need for durable, chemically resistant lining materials is critical. Basic refractories play a central role in protecting equipment and optimizing furnace performance. At Ranchi Refractories, we manufacture and supply high-performance basic refractory solutions tailored to withstand the harshest environments.

What Are Basic Refractories?

Basic refractories are materials that exhibit strong resistance to basic slags, lime, and other alkaline compounds. Their chemical composition is predominantly based on magnesia (MgO) and dolomite (CaO·MgO), making them ideal for use in environments where acidic slags would rapidly degrade other types of refractories.

These refractories are called “basic” because they are stable in basic (alkaline) chemical environments, in contrast to acidic or neutral refractories.

Key Types of Basic Refractories

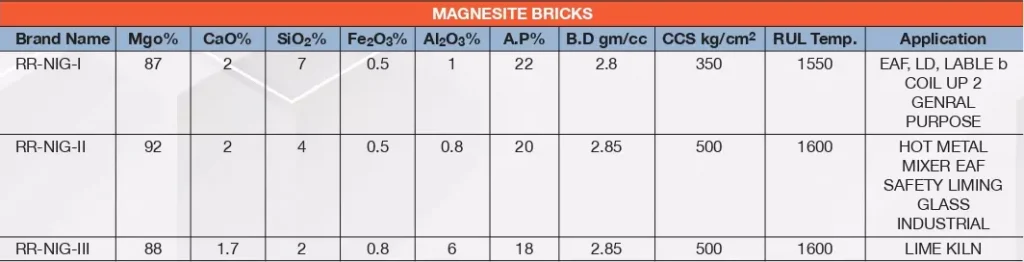

Magnesite Bricks

Composed primarily of magnesium oxide, these bricks offer excellent resistance to basic slags and high temperatures. Used extensively in steel ladles, converters, and rotary kilns.Dolomite Bricks

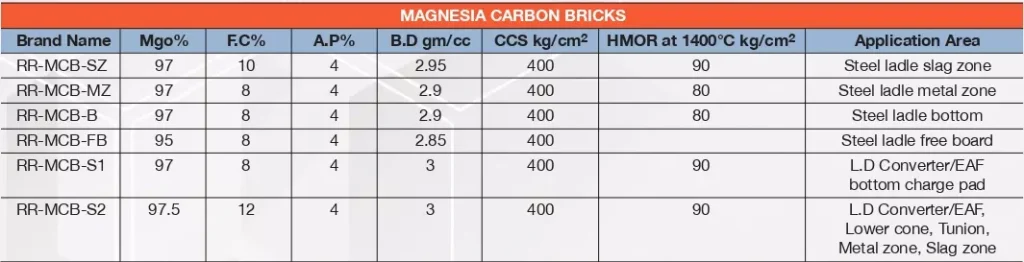

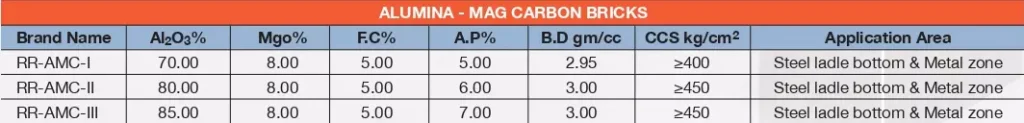

Made from sintered or calcined dolomite, they have excellent hydration resistance and are often used in basic oxygen furnaces (BOFs) and AOD converters.Magnesia-Carbon Bricks (MgO-C)

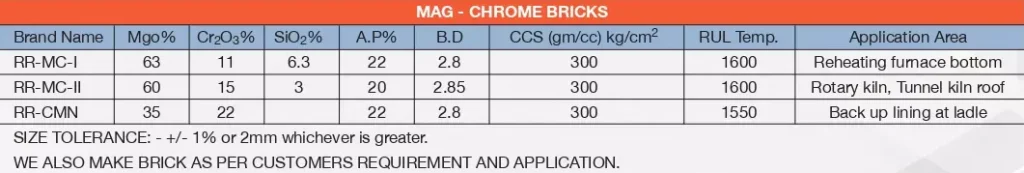

A composite material combining magnesia and graphite. They offer superior thermal shock resistance, slag resistance, and are widely used in electric arc furnaces (EAFs) and ladle linings.Magnesia-Chrome Bricks

These are high-density bricks with strong slag resistance, used in non-ferrous metal industries, cement kilns, and other high-wear areas.

Applications Across Industries

Steel Industry: Linings for basic oxygen furnaces, EAFs, ladles, and converters.

Cement Industry: Rotary kilns, coolers, and calciner linings.

Non-Ferrous Metallurgy: Furnaces for copper, nickel, and lead smelting.

Lime and Dolomite Plants: Lining of shafts and kilns exposed to high basicity.

Advantages of Basic Refractories from Ranchi Refractories

✅ High Refractoriness: Capable of withstanding temperatures above 1,700°C.

✅ Chemical Resistance: Excellent stability in basic slag and lime-rich environments.

✅ Thermal Shock Resistance: Especially with MgO-C grades.

✅ Customized Solutions: Tailored to client-specific furnaces, processes, and wear zones.

✅ Consistent Quality: Manufactured under strict QA/QC processes using premium raw materials.

Why Choose Ranchi Refractories?

With decades of experience in the refractory industry, Ranchi Refractories has established itself as a trusted partner for steel plants, cement kilns, and metallurgical operations across India and abroad. Our product development is backed by on-ground insights, enabling us to deliver refractory linings that perform reliably under extreme conditions.

Facilities for Manufacturing Basic Bricks:

Automated Electric Screw Press . ESP 800T . ESP 630T . High Temperature Tunnel Kiln 1750oC . Tempering Kiln . High Intensive . Counter Current Mixer . Ball Mill . Jaw Crush

- 19/20 N Ancillary Industrial Area, Tupudana, Hatia, Ranchi - 834002

- +91 651 2290628

- +91 8051039435

- sales@ranchirefractories.com